General:

El concepto de vehículo no tripulado no es nuevo y es utilizado por el ejército desde la Segunda Guerra Mundial. El progreso en la tecnología de control de vuelo, los motores sin carbones y el bajo coste de los diversos componentes junto con los módulos de a bordo: Wifi, cámara, GPS, sensores de visión, etc., han hecho que la tecnología esté disponible para la mayoría de los entusiastas de la tecnología, incluidas las corporaciones gigantes. Mientras servía en el ejército, tuve el privilegio de lanzar un proyecto para usar quadcopter para la vigilancia inmediata en el campo de batalla. Es innecesario decir que en 2008, esta tecnología estaba en su etapa inicial para fines comerciales o para apoyar una producción escasa. La tecnología de control de vuelo estaba evolucionando, el tamaño miniatura en la CPU integrada a bordo acaba de aparecer en el mercado, los simuladores de vuelo eran pocos y, por supuesto, los fondos eran escasos. Desarrollamos un prototipo utilizando bambúes como hélices para evitar la detección de RADAR y reducir la firma EM.

Tras solo doce años de avance, se está alzando como uno de los productos tecnológicos más vibrantes del mercado. Ya sea para recolectar muestras para pruebas de laboratorio desde el lugar más remoto de Fete (una aldea remota en Costa de Marfil) para entregar mercancías de lujo en Manhattan o Madrid, o para anunciar el uso de máscaras protectoras por parte de los ciudadanos en Wuhan,

o plantar árboles;

El uso de drones está limitado solo por la imaginación.

Alcance:

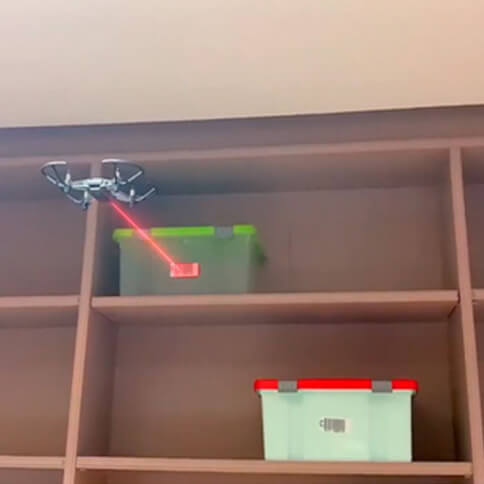

En este artículo enumeramos los desafíos que enfrentan los almacenes para el inventario en tiempo real, el estado tecnológico actual, incluido el desarrollo de prototipos, nuestros objetivos y el enfoque para abordar los desafíos. Puedes ver nuestro POC aquí …

Desafíos:

Los desafíos a los que se enfrentan en los almacenes:

- Los almacenes que utilizan códigos de barras, realizan inventarios y contabilidad ocasionales debido a la participación de costos y tiempo.

- La validación y verificación del inventario con códigos de barras requiere recursos humanos expertos.

- La visibilidad de los activos o mercancías tiene un retraso de tiempo debido al tiempo de latencia del seguimiento y luego de cargar los datos (algunos de los depósitos avanzados mitigaron este retraso a través de la integración de escaneo y carga en tiempo real).

- El uso de RF ID activa no es rentable para mercancías de bajo valor.

- Las etiquetas pasivas de identificación de RF pueden generar una potencia limitada, por lo tanto, necesita un potente lector de identificación de RF.

- Los paquetes / mercancías se apilan en dos o tres capas, lo que requiere la intervención humana para permitir que el lector de códigos de barras lea los códigos de barras.

- La mercancía en almacenes al aire libre se dispersa en un área grande de manera aleatoria, lo que agrega más dificultades en el inventario de códigos de barras.

- Algunos de los almacenes tienen poca visibilidad, lo que afecta la calidad de la imagen.

Estado tecnológico actual:

Los principales desafíos para los drones no tripulados que se utilizarán en almacenes interiores y exteriores son, la potencia, la navegación y el rango de vuelo. Algunos intentos para abordar estos desafíos son:

- Usando drones atados, podemos tener poder continuo y conectividad de datos. Pero la correa tiene una limitación de alcance (no es adecuada para el inventario al aire libre), el dron debe tener un mínimo capacidad de levantamiento de pesas que denota su mayor tamaño y no son adecuadas para operar cómodamente dentro de los almacenes por dos razones: atadura y GPS (que es inexacto dentro de los almacenes interiores). La mayoría de estos drones son drones personalizados, lo que significa un coste más alto y el sistema de amarre también tiene un coste. Algunas de las compañías que ofrecen estos servicios son Elistair, Alltechuav, Hoverfly, Lifeline.

- Algunas de las compañías que ofrecen este producto aún se encuentran en la fase de I + D, donde el dron puede recargarse mientras se cierne o podemos llamarlo carga inalámbrica en vuelo:

- Esto abre una nueva era en la tecnología de drones donde podemos tener múltiples estaciones de carga en ruta para drones como tenemos estaciones de carga de gas / combustible / electricidad para automóviles. Esto se puede usar en el inventario del almacén al aire libre siempre que el costo sea asequible.

- También hay estaciones de acoplamiento de drones donde puede atracar, cargar y volar de nuevo; Estas estaciones son útiles para el inventario de almacén al aire libre y pueden integrarse con la solución de gestión de inventario:

- Para la navegación interior, podemos utilizar balizas que deben fijarse en diferentes lugares del almacén y también en los drones, lo que permite localizar y controlar la ruta de vuelo.

- Los investigadores del MIT han adoptado una solución para drones de interior donde los drones llevan un repetidor y etiqueta de identificación de RF y, por lo tanto, pueden escanear identificaciones de RF pasivas y determinar la ubicación de los drones dentro de unos pocos centímetros; esto todavía está en pruebas:

Objetivos:

Establecemos los siguientes objetivos en función de los desafíos que enfrentan los almacenes y el estado actual de la tecnología de drones:

- Nuestra solución debe permitir el inventario de códigos de barras en el almacén en tiempo real bajo demanda por drones si hay un pasaje para que un humano camine por el corredor con poca visibilidad.

- Nuestra solución debe permitir el inventario de almacenes al aire libre en tiempo real a pedido mediante códigos de barras o etiquetas de identificación RF.

- Nuestra solución debe ser de bajo coste pero altamente efectiva y atractiva.

Especificación de la aplicación:

Estamos utilizando drones Ryze y DJI para lograr los objetivos mencionados anteriormente. Hemos desarrollado nuestro propio algoritmo para identificar la ubicación precisa del dron en los almacenes interiores sin utilizar balizas de terceros o GPS; a través del cual podemos planificar una ruta de exploración y posiciones. A medida que el dron escanea los códigos de barras, se crea un archivo JSON / XML y se carga utilizando la API CRM / ERP del cliente. Utilizamos enjambres de drones para realizar una tarea de escaneo más rápido. Para el inventario de almacén al aire libre utilizamos drones DJI con nuestra propia aplicación.